Energy Audit for Commercial

A GeoHeat Energy Audit / Energy Saving Assessment will identify potential energy efficiency improvements for your business.

Reduce Your Energy Costs Increase Your Profits

Australian businesses are struggling with:

- Uncertainty in the energy market

- A doubling of gas prices since January 2017

- Having the most expensive electricity prices in the world

Your business can survive these difficult times by avoiding unnecessary energy expenditure before it is too late. GeoHeat can assist you with identifying cheaper energy resources, such as geothermal and solar thermal, to cut your bills.

In the past, many businesses have just considered energy cost as “a cost of doing business”. However, now, by running an inefficient or expensive energy system, you are overpaying for energy and unnecessarily losing profits. It just doesn’t make any sense.

For new-built developments, NCC ensures that your energy system meets its Section J requirements, however, choosing between these systems and their integration with renewables is the key to the energy cost saving.

A good commercial energy assessment will point the way to reduce your energy costs by 10% to 50% per annum. For a moderately sized greenhouse grower, this amount can be substantial, and could mean the difference between staying afloat or going out of business..

Identifying cheaper energy resource

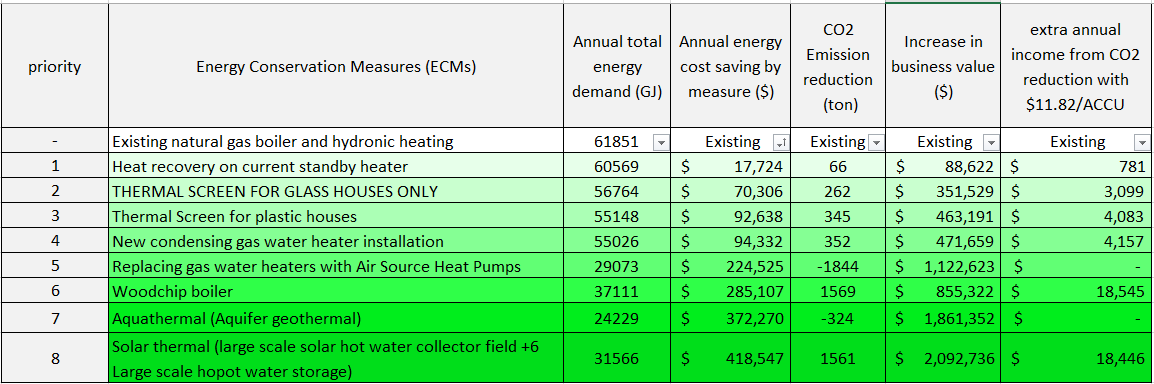

We Identify the Best Energy Efficiency Measures for your Business

There are a multitude of vendors peddling their energy efficient solutions, which are supposed to save energy. Most of them do, but some don’t. In any case, just because a device saves on energy costs does not make it a good investment. To establish what a good investment is, it is important to ask how much the solution will save on annual energy costs.

For instance, a battery storage solution for a dairy farm may save on energy consumption costs, however, the savings might not be big enough to pay back for the initial investment, and after few years when the battery life has ended, you might find that the whole investment cost is more than its savings.

So, how do you determine what the best energy efficiency measures (EEM) are for your business? That is what GeoHeat Energy Assessments and Energy Audits are for. With our past experiences following BESS Best Practice measures for Victorian developments and Green Star Rating for NSW, we are confident that our solutions will satisfy your needs and elevates you in the industry.

Some Examples of GeoHeat Energy Efficiency Measures to

Save Energy

Minimizing Unwanted Infiltration

Introducing a Variable Boiler Set Point

Adding Heat Pipes to Increase Efficiency

Pumping CO2 from a Boiler Flue to Hothouses

Heat Pump Heating

Finding a Cheaper Energy Source

Reduce Waste Energy

Aqua-thermal Energy from Irrigation Water

Contact us to discuss how we can assist you with commercial energy saving assessment.

Reduce waste energy by Increasing insulation on hot water distribution pipes and buffer tanks

The first simple measure to increase energy efficiency is minimizing the waste energy. Insulation can be applied to the energy distribution pipes and some areas of the hothouses. For instance, heat loss from a hot water pipe can be reduced by 60% with using 10mm thick insulation and by 77% by using 25mm Rockwool insulation. Depending on the lengths of pipes that are exposed to ambient temperature, recommendations for this measure can be finalized.

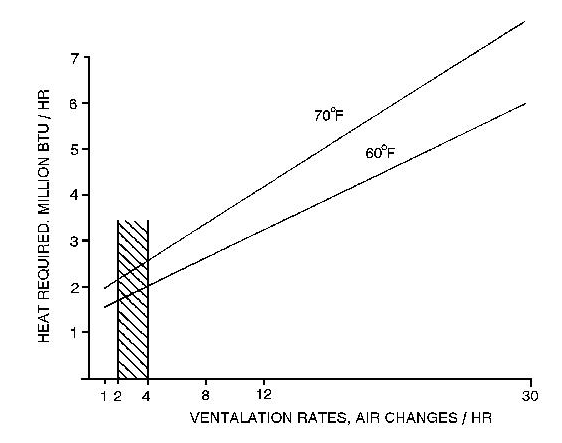

Minimizing Infiltration

High and unwanted Infiltration is in most cases the main factor that contributes to higher demand. The ventilation systems shall be checked continuously to make sure infiltration is as low as possible during heating periods. Halving the unnecessary infiltration can save about 30% of required heating costs.

Injecting CO2 from boiler flue to hothouses

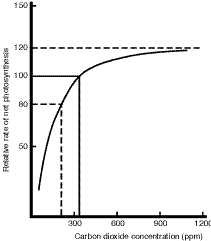

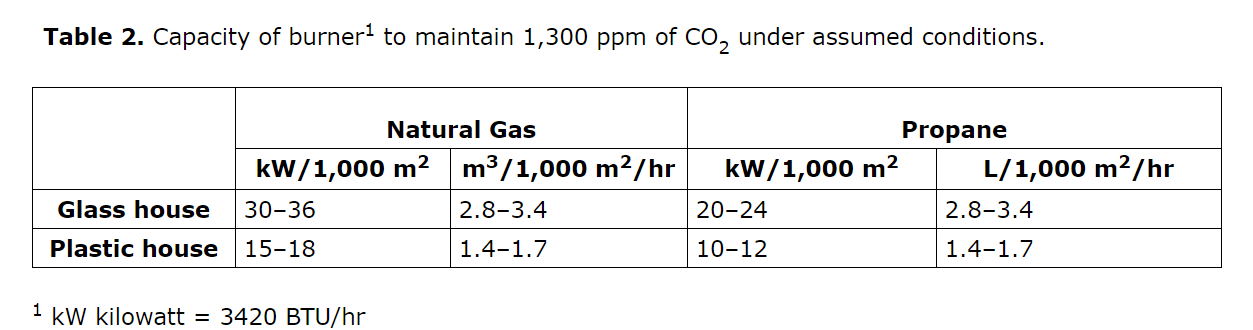

Thought the energy benefits are not considerable in this case, the co-benefit is increased productivity as crops consume CO2 in photosynthesis. As CO2 levels are raised by 1,000 ppm photosynthesis increases proportionately resulting in more sugars and carbohydrates available for plant growth. Any actively growing crop in a tightly clad greenhouse with little or no ventilation can readily reduce the CO2 level during the day to as low as 200 ppm. The decrease in photosynthesis when CO2 level drops from 340 ppm to 200 ppm is similar to the increase when the CO2 levels are raised from 340 to about 1,300 ppm

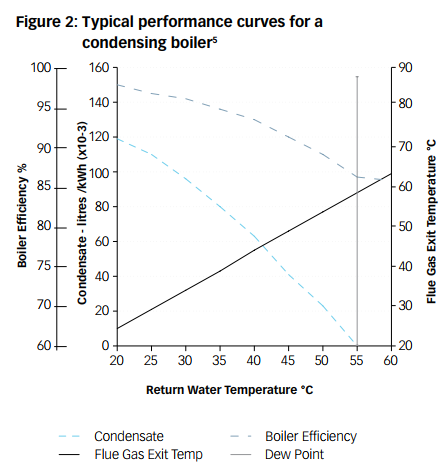

Changing heating automation logic and introducing variable boiler set point

Boilers efficiency improves when the leaving water from the boiler is at lower temperatures. To reduce the boiler set point and yet satisfy the variable demand, we suggest changing the automation logic from a single set point to a variable set point for the boiler. The boiler set point can be automated to be reduced when outdoor temperature rises to allow maximizing the efficiency of the boiler. This automation can be simply implemented by the addition of a single temperature sensor which measures the ambient temperature and adjusts the boiler set point based on the ambient temperature. The figure bellow shows that matching the boiler output temperature with demand can improve efficiency by 15% which is about $135K saving for the business owner.

The co-benefits of this measure is also increased boiler lifespan as corrosion rate reduces by the reduced operating temperature of the boiler.

Addition of more heat pipes to increase the efficiency of the boiler

Another method to increase boiler efficiency is by increasing the surface area of the heat pipes to allow delivering the same heat in kW with hot water at lower temperature. Similar to the measure discussed above, this will allow to permanently reduce the set point levels and improve the boiler running efficiency.

The co-benefit of this measure is increased the productivity by increasing crop growth. Based on a study at the University of Wisconsin, It is suggested to utilize plastic HDPE pipes instead of steel pipes as heat pipe as they are far cheaper and easier to install. Based on a recent purchase for a client, the price of 25mm HDPE pipe is $0.7/m which offer an easy and affordable option for this measure.

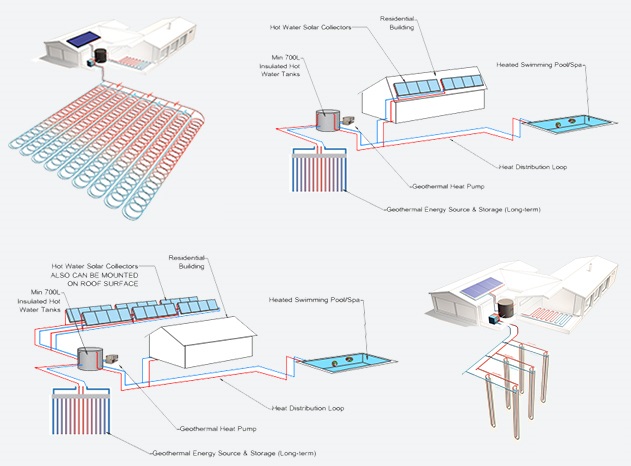

Heat pump heating

Most of the heating demand for a greenhouse is during electricity off-peak hours which makes electric heat pump heating a viable option. During the night (11Am to 6AM), power generators run at their lowest capacity as demand drops and retailers offer electricity at almost half the cost of electricity during the day. This is a great cost-saving opportunity for businesses with high heating demand during the night to use. a Geothermal heat pump or air source heat pump can be used to deliver hot water for hydronic heating. Geothermal heat pumps can extract energy from the ground, groundwater and irrigation dams which have a higher and more stable temperature than air and hence can operate far more efficient than other types of heat pumps. Refer to our Geothermal page to read more about geothermal technology.

Air source heat pumps are not as efficient than geothermal heat pumps but they can still offer benefit in compared to expensive liquid or natural gas.

The efficiency of heat pumps varies from 250% in case of air source heat pump to 550% geothermal heat pumps. This means for delivering, for instance, 100kW heating energy, 40kW to 18kW (in the case of geothermal) is needed and when half price offpeak electricity is factored in the analysis, it may make sense to switch to heat pump heating during the night.

Use of Gas Heat Pumps

Gas heat pumps are cheaper to run in Australia. They might be more expensive to install and maintain but it is worthwhile to consider the economy of this option for the Piovillico business.

The co-benefit of this measure is reduced GHG emissions as gas is by far more cleaner (about 5 times) in compared to electricity generated in Victoria with brown wet coal.

Replacing the source of energy

Use of Aqua-thermal energy in the irrigation dam

Gas heat pumps are cheaper to run in Australia. They might be more expensive to install and maintain but it is worthwhile to consider the economy of this option for the Piovillico business.

The co-benefit of this measure is reduced GHG emissions as gas is by far more cleaner (about 5 times) in compared to electricity generated in Victoria with brown wet coal.

Sustainability Victoria Energy Assessment grant

As of May 2018, Sustainability Victoria is offering two non –competitive energy assessment grants for businesses spending over $20,000 a year on energy:

- Basic energy assessment grant: Up to $2000 towards the cost of a basic energy assessment and a further $3000 bonus to implement energy efficiency actions. This is recommended for businesses spending between $20,000 to $50,000 on energy per annum.

Funding example: For an assessment quoted at $2600, Sustainability Victoria (SV) funds $2000, the business funds $600. The assessment report recommends an energy saving project costing $3000, SV funds the $3000 to undertake the project.

- Detailed energy assessment grant: Half the cost of an assessment up to $15,000 and a further $5000 bonus to implement energy efficiency actions. This is recommended for businesses spending more than $50,000 on energy per annum.

Funding example: For an assessment quoted at $8200, SV funds $4100, the business funds $4100. The assessment report recommends an energy saving project costing $5000, SV funds the $5000 to undertake the project.

As this is a non-competitive program, a Business Productivity team adviser is available to guide you through the application process.

GeoHeat has been involved in this program for a long time and we are one the approved assessors with Sustainability Victoria. GeoHeat’s energy assessments are based on or equivalent to a Type 2 Energy Assessment (Australian Standard AS/NZS AS3598.1:2014, AS/NZS S3598.2:2014). You can read more about this grant here.

Contact us for our state of art energy assessing today

Need more information or a quote?

Speak to our experts or get a quote now!

Contact us:

Address:

24 Aisbett Avenue,

Camberwell, vic 3124

ABN:

27610168842

GEOFLOW AUSTRALIA PTY LTD