Clean, Efficient & Renewable

Geothermal Energy

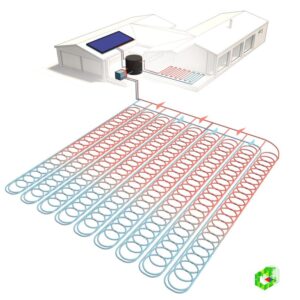

Geothermal heating and cooling systems simply move heat from the ground to the building and generate as much as 4-5 units of heat for every 1 unit of electricity used.

Water is circulated inside poly pipes that are buried in the ground, and a small box (i.e. heat pump) pumps free heated water from the ground to the building. The energy from the heated water is then circulated around the building via either hot water pipes (i.e. hydronic heating) or heated air (i.e. ducted heating).

In cooling mode, the system simply works in the opposite direction. It takes heat from the building and rejects it into the ground. The ground’s high thermal mass and year-round constant temperature, allow it to be one of the most efficient energy resources for heating and cooling buildings. Complete geothermal systems are not an off-the-shelf product, and in order to deliver the highest efficiency, they have to be properly designed and sized by a qualified professional.

Aside from energy efficiency, the geothermal system is probably the best solution for Ecologically Sustainable Developments (ESD). Also, if you are aiming for a high Green Star Rating, a geothermal system as a proposed heating/cooling service does the job just fine compared to the conventional reference services such as water-cooled or air-cooled heat pumps.

Geothermal system has a higher COP (or rather efficiency) compared to conventional heating and cooling heat pump and thus, it generates less amount of greenhouse gas emissions. To comply with the energy efficiency provisions of NCC Section J through verification methods (e.g. JV3 alternative solution), is to emit less greenhouse emissions compared to an NCC reference building with reference services. Buildings with a geothermal system installed could comply easily with the code while managing to use this offset to have low-cost windows, non-insulated heritage walls or higher artificial lighting power densities than allowed by the code. For residential buildings, the above benefits are not applicable through verification method or star rating and the decreased energy bills is the sole benefit of geothermal systems for residential dwellings.

Just as in the solar electricity industry, a business that simply pays for a membership within a geothermal industry association is not proof that they are qualified to properly engineer a system. What makes GeoHeat different to the others is that GeoHeat is the only geothermal company in Australia with an Australian Certified Geothermal Designer (CGD).

Advantages of Geothermal

- Extremely efficient operation

- Can provide heating, cooling and domestic hot water

- Long life (a closed ground-loop system can last 50+ years)

- Low maintenance

- No outdoor unit

- Quiet operation

- Can be combined with solar thermal as energy storage for solar thermal systems

Applications

- Residential heating/cooling

- Commercial heating/cooling

- Domestic hot water generation

- Swimming pool heating

- Industrial / agriculture heating and cooling

Geothermal is Twice As Efficient than a Daikin Inverter-Driven VRF System

The new ASHRAE headquarters building In Atlanta (US) is a living laboratory. It is extensively instrumented to compare the performance of an inverter driven VRF system for level 1, and a geothermal system for level 2. In 2008, part of the results were published, and it was concluded that the geothermal system used 98% less electricity than the VRF system.

In Slab Heating & Cooling

Geothermal heat pumps come in both water-to-air, and water-to-water types. The latter is the most common, and works best with hydronic heating and cooling.

The large surface area of a hydronic geothermal system enables it to run at higher efficiency. In-slab cooling can satisfy the majority of the cooling requirements of the building when simply combined with ceiling fans. Alternatively, chilled-water fan coils and chilled beams can be used for cooling the building.

Geothermal heating and cooling systems simply move heat from ground to building and generate as much as 4-5 units of heat for every 1 unit of electricity used. Water is circulated inside poly pipes buried in the ground and a small box (heat pump) pumps free heat from ground to the building in hot water (hydronic heating) or heated air (ducted heating). In cooling mode, it works exactly in opposite and takes heat from the building and rejects it to ground. The ground high thermal mass and constant temperature throughout the year allows it to be one of the most efficient energy resources for heating and cooling buildings. geothermal systems are not an off the shelf product and in order to deliver the highest efficiency, it has to be properly designed and sized. What makes us different in Geothermal field is that GeoHeat is the only geothermal company in Australia with an Australian Certified Geothermal Designer (CGD) on board and we have the highest qualification in this industry.

Different Layout Options for Geothermal Systems

Horizontal

Horizontal ground pipes in trenches, or in a large open pit, are usually most cost-effective when an adequate area is available around the building and the ground is easy to dig with an excavator. The most common ground pipe layout is Slinky-style …

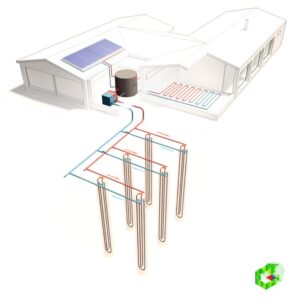

Vertical

Vertical geothermal piping systems are for buildings that have limited land area available to install the geothermal ground pipes. A set of boreholes are drilled, and ground pipes are installed and grouted …

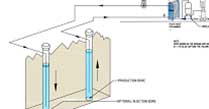

Water loop

Water loops are an innovative use of available bodies of water in the close vicinity of the building. A closed-loop pipe system is submerged into irrigation water dams, lakes or ponds to get energy from the body of water …

Open loop

In open-loop systems, clean bore water or surface water, is directly circulated through the heat pump to transfer energy to/from the available water supply. The water is returned to the bore or the surface water …

Energy piles

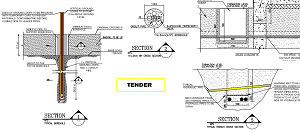

Geotechnical structures such as piles, tunnels, sewers, retaining walls and ground slabs can be regarded as a ground heat exchanger by simply embedding ground loop pipes in them. Energy Piles are mostly …

6-Star Energy Assessment

The GeoHeat Energy team provides a clear, concise and most detailed approach to achieving energy compliance, and at the same time, minimizes the heating and cooling demand of the building by proposing passive solar principles for the building.

Passive Solar House

Good buildings are designed to passively take advantage of the local climate to maintain thermal comfort. At GeoHeat, we use appropriate strategies and take into account the climate and specifics of the site to quantitatively minimize the heating and cooling …

Geothermal Ground Heat Exchanger Design

GeoHeat works collaboratively with architects and mechanical design teams to assist with the design of the geothermal ground pipes (ground heat exchangers) to deliver cost-effective geothermal systems with minimum ground works. Mechanical design …

Hydronic & Ducting

Hydronic and ducted air systems are the two most common methods for delivering the heating and cooling energy inside the building. Correct sizing is the key to assure comfort for the building residents in all areas at all times …

We offer turnkey solutions to architects, clients and design teams to deliver truly outstanding high-performance buildings.

From planning and concept design, through to proven operational performance, GeoHeat offers in-depth sustainability services that provide real value throughout the project timeline – reflecting our commitment to efficient performance and our up-to-date approach.

We assist firstly, by minimising energy requirements via applying engineered passive solar design solutions, and only then, do we introduce the geothermal heating and cooling system as one of the most efficient heating and cooling systems available. We also provide a design and cost analysis for a conventional heating and cooling system so the client/design team can see the real benefits of the geothermal system.

6-Star Energy Assessment

The GeoHeat Energy team provides a clear, concise and most detailed approach to achieving energy compliance, and at the same time, minimizes the heating and cooling demand of the building by proposing passive solar principles for the building.

Passive Solar House

Good buildings are designed to passively take advantage of the local climate to maintain thermal comfort. At GeoHeat, we use appropriate strategies and take into account the climate and specifics of the site to quantitatively minimize the heating and cooling …

Geothermal Ground Heat Exchanger Design

GeoHeat works collaboratively with architects and mechanical design teams to assist with the design of the geothermal ground pipes (ground heat exchangers) to deliver cost-effective geothermal systems with minimum ground works. Mechanical design …

Hydronic & Ducting

Hydronic and ducted air systems are the two most common methods for delivering the heating and cooling energy inside the building. Correct sizing is the key to assure comfort for the building residents in all areas at all times …

We offer turnkey solutions to architects, clients and design teams to deliver truly outstanding high-performance buildings.

From planning and concept design, through to proven operational performance, GeoHeat offers in-depth sustainability services that provide real value throughout the project timeline – reflecting our commitment to efficient performance and our up-to-date approach.

We assist firstly, by minimising energy requirements via applying engineered passive solar design solutions, and only then, do we introduce the geothermal heating and cooling system as one of the most efficient heating and cooling systems available. We also provide a design and cost analysis for a conventional heating and cooling system so the client/design team can see the real benefits of the geothermal system.

Geothermal Heating and Cooling

Geothermal systems efficiently heat and cool buildings using sustainable geothermal energy accessed via geothermal ground loops. In closed-loop systems, geothermal ground loops comprise pipes embedded in small diameter drilled boreholes or 1m wide trenches or even built into foundations, all within a few tens of metres from the surface. The geothermal systems are just starting to be generally known in Australia with relatively few, but highly varying and diverse installations to date offering a potentially economically viable and environmentally friendly method for heating and cooling of buildings.

Geothermal systems efficiently heat and cool buildings using sustainable geothermal energy accessed via geothermal ground loops. In closed-loop systems, geothermal ground loops comprise pipes embedded in small diameter drilled boreholes or 1m wide trenches or even built into foundations, all within a few tens of metres from the surface. The geothermal systems are just starting to be generally known in Australia with relatively few, but highly varying and diverse installations to date offering a potentially economically viable and environmentally friendly method for heating and cooling of buildings.

Geothermal systems require ground works like excavation or drilling to bury the geothermal ground loops. This is the major difference between a geothermal system and any conventional heating and cooling system. The ground works lead to higher capital costs for installation. The design of geothermal ground loops in Australia is mostly achieved with simple rules of thumb.

The high capital cost of geothermal ground loop installation is one of the main causes preventing wide adoption of direct geothermal systems in Australia. It is therefore imperative that geothermal ground loops should be designed as efficiently as possible to minimize the extent and cost of geothermal installation.

At GeoHeat, we are using the design methods from the International Ground Source Heat Pump Association (IGSHPA) that is based in the University of Oklahoma. We combine it with the latest version of TRNSYS for numerical modelling. TRNSYS is the most robust thermal modelling software that allows modelling geothermal system in addition to the building modelling and almost any other renewable energy system. Our unique design technique ensures that the geothermal ground loops are sized to the needs of the house and under-sizing and over-sizing the heating and cooling system are avoided.

Principal Elements of a Geothermal System

The principal elements of a direct geothermal heating and cooling system are shown in the figure below

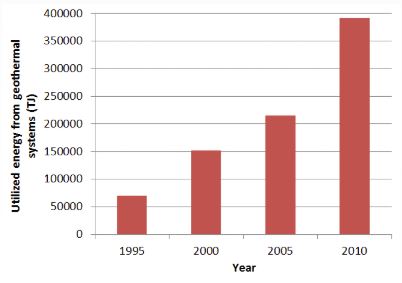

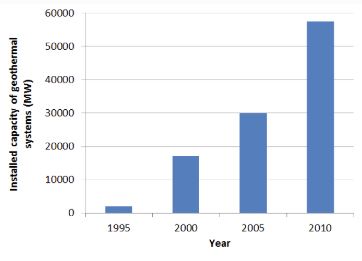

• The heating and cooling demand of the building, The key to the direct geothermal system is that for each kilowatt of electrical energy put into a direct geothermal system, depending on several parameters, about 4-5 kilowatts of energy is developed for the purposes of heating and cooling. This means that direct geothermal systems could reduce electricity demand for heating and cooling by 75%. Furthermore, as much of the electrical power in Victoria is generated with brown coal, replacing 75% of the energy used with a clean and free renewable energy source, geothermal systems will have the potential to significantly cut Australia’s carbon footprint. It is estimated that there are over 3 million direct geothermal systems installed around the world, with the total installed capacity approximately doubling every 5 years since 2000 (Lund et al., 2010). The figure below shows the growth rate of the installed capacity and annual utilization of all forms of geothermal energy for heating and cooling applications (Lund, 2010). In the following, each of the elements of a direct geothermal system is discussed in more detail.

• The Ground Source Heat Pump (GSHP) which causes heat to flow “uphill” from lower temperature to higher temperature,

• The geothermal ground pipes buried within a few tens of metres of surface as a heat source in winter and heat sink in summer.

A heat transfer fluid (typically water) is circulated through geothermal ground loop pipes and exchanges heat with the surrounding ground. If the fluid is cooler than the ground, the ground will heat it and if the fluid is hotter than the ground, it will be cooled. GSHPs efficiently upgrade the heat extraction/rejection process. In the winter, the heat pump removes heat from the heat exchanger and pumps it into the indoor heat delivery system. In the summer, the process is reversed, and the heat pump moves heat from the indoor air into the geothermal ground loops and the ground. Read more

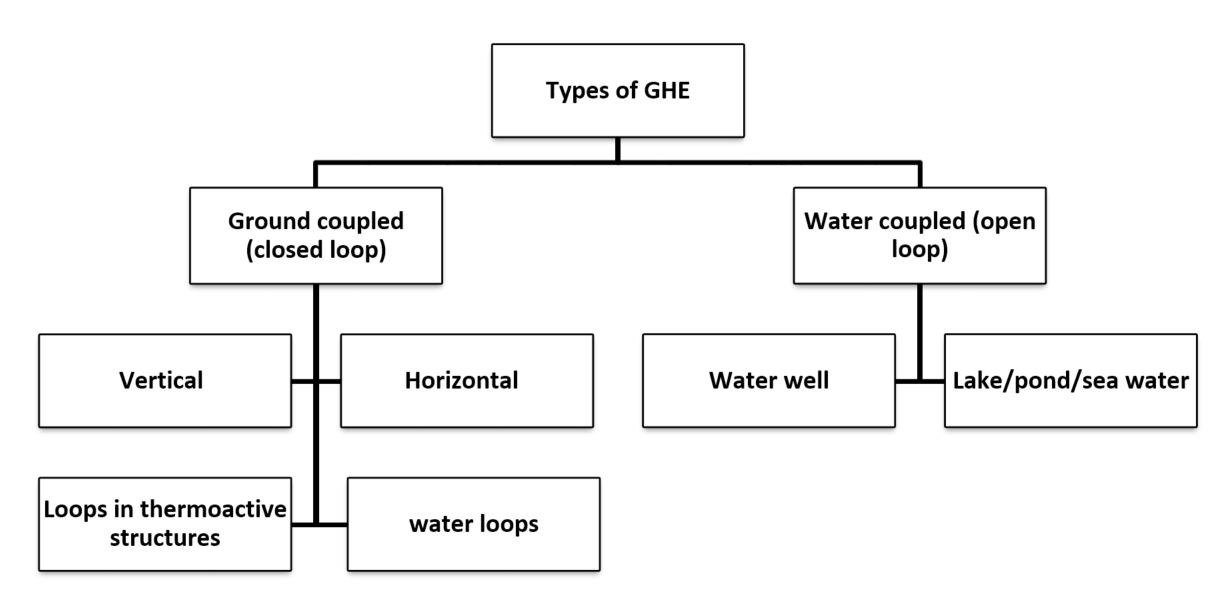

Types of Geothermal Ground Loop Configuration

Different geothermal ground loop configurations are classified in Figure below.

Closed loop geothermal ground loops comprise pipes placed in the ground or water through which a fluid circulates and the heat exchange occurs by conduction through the walls of the pipes. Therefore, the fluid remains sealed in the pipes and does not come into contact with the energy storage medium. There are several advantages to this system. One of the main advantages is that there is no problem of contamination either from the loop water entering the ground or perhaps more critically, from the groundwater contaminating the workings of the pumps.

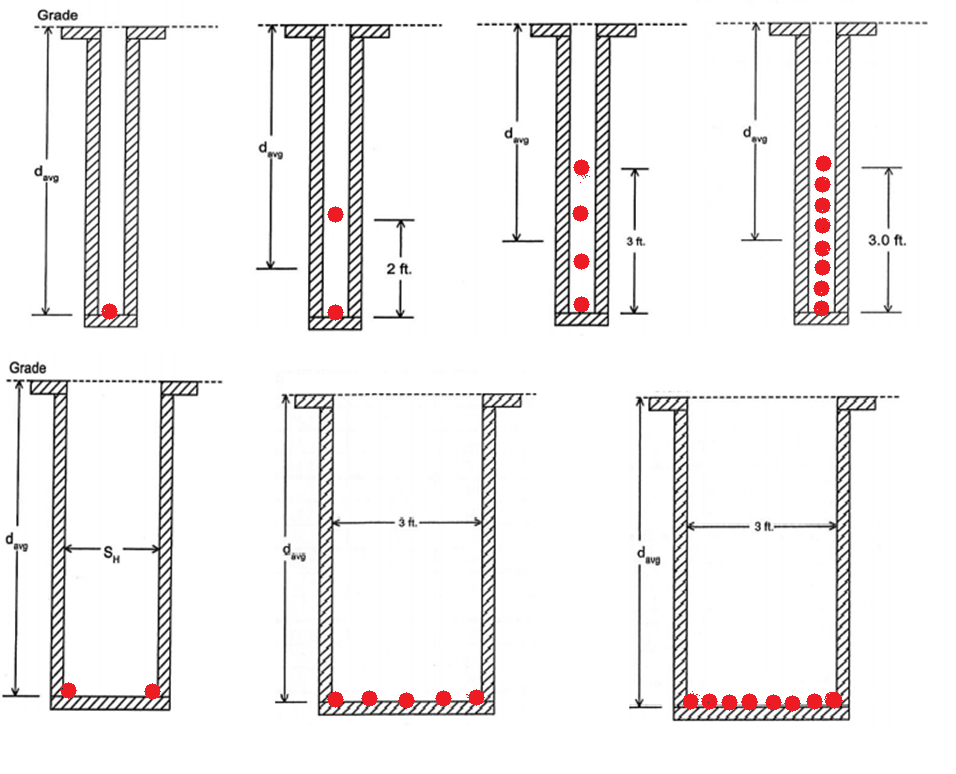

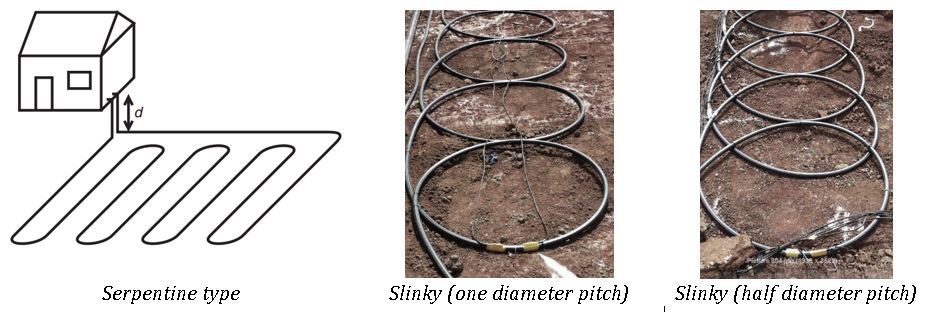

Horizontal Ground Heat Exchanger

Horizontal trenches are usually the most cost-effective when the adequate area is available around the building and trenches are easy to dig. The spacing between geothermal trenches is 2-3m and each trenches is 24 or 48 m long. Figure below shows different configurations of horizontal geothermal ground loop that can be constructed. The horizontal geothermal ground loop has become increasingly popular due to its low cost and ease of installation. For instance in Canada, in 2011, about 55% of direct geothermal installations use horizontal geothermal ground loop (CGC, 2011). Nevertheless a horizontal geothermal ground loop requires a large area of ground to lay the pipe network. This problem can be alleviated to some extent by employing a slinky loop arrangement of the pipes. Slinky arrangements are coils of overlapping piping, which are spread out and laid either horizontally or vertically. This geothermal ground loop’s ability to focus the area of heat transfer into small volume reduces the length of the trenches by 20-30% of those for single pipe configuration (Wu et al., 2010). The slinky coils can have different lengths per unit length of trench depending on the pitch spacing of successive coils. The performance of slinky coils is similar to straight pipes with an equivalent total length.

(note: the pipes in red are not to scale for better visibility)

Vertical Ground Heat Exchanger

Where there is a confined surface area or minimum disruption of the landscape is desired, a geothermal ground loop in form of vertical boreholes (of varying diameter) comprising one or more “U-loops” of high-density polyethylene (HDPE) pipe are installed in a borehole backfilled with cement/bentonite grout. Boreholes are installed 5-8m spacing between boreholes to minimize thermal interference between boreholes. Each borehole is drilled down to 30-50m and in some case down to 100m. The borehole depth for vertical geothermal ground loop depends on soil or rock type, required heating and cooling capacity of each borehole and capabilities of the local drillers. If there is access to a local drilling rig that can drill down to 40m cost-effectively, GeoHeat will most probably recommend it to bring down the capital cost of installation and will install more boreholes so that total geothermal ground loop depth is satisfied. Vertically bored geothermal ground loops encounter the largest variation in the soil and rock conditions resulting in a wide range of heat transfer capabilities that have, along with grout and thermal properties, a large effect on the required length of the borehole to achieve the necessary heat transfer to or from the ground.

Where there is a confined surface area or minimum disruption of the landscape is desired, a geothermal ground loop in form of vertical boreholes (of varying diameter) comprising one or more “U-loops” of high-density polyethylene (HDPE) pipe are installed in a borehole backfilled with cement/bentonite grout. Boreholes are installed 5-8m spacing between boreholes to minimize thermal interference between boreholes. Each borehole is drilled down to 30-50m and in some case down to 100m. The borehole depth for vertical geothermal ground loop depends on soil or rock type, required heating and cooling capacity of each borehole and capabilities of the local drillers. If there is access to a local drilling rig that can drill down to 40m cost-effectively, GeoHeat will most probably recommend it to bring down the capital cost of installation and will install more boreholes so that total geothermal ground loop depth is satisfied. Vertically bored geothermal ground loops encounter the largest variation in the soil and rock conditions resulting in a wide range of heat transfer capabilities that have, along with grout and thermal properties, a large effect on the required length of the borehole to achieve the necessary heat transfer to or from the ground.

Water Loop Heat Exchanger

Where there is a body of water in the form of a dam or lake within a reasonable distance from a building, these surface water bodies can also be considered as an energy source.Water loops are gaining popularity because they require no drilling or excavation. These systems, due to an efficient heat exchange interface, potentially require less piping than other geothermal ground loop configurations. In closed water loops, HDPE coils are attached to a frame and submerged in a water body. The coils are typically supported 0.5m above the lake bottom to allow for convective flow around the piping. Normally the coils should have at least 1.8m of water above them (Self et al., 2012). It is necessary to assure sufficient thermal mass is maintained during low water conditions and prolonged droughts. The CGC (2010) also mentions that in cold climates, if a water body depth is less than 3m, lakes and dams destratify and offer no advantage. Due to flooding and droughts as well as hazards due to moving debris that can damage the geothermal ground loop, rivers are not ideal for this application.

Where there is a body of water in the form of a dam or lake within a reasonable distance from a building, these surface water bodies can also be considered as an energy source.Water loops are gaining popularity because they require no drilling or excavation. These systems, due to an efficient heat exchange interface, potentially require less piping than other geothermal ground loop configurations. In closed water loops, HDPE coils are attached to a frame and submerged in a water body. The coils are typically supported 0.5m above the lake bottom to allow for convective flow around the piping. Normally the coils should have at least 1.8m of water above them (Self et al., 2012). It is necessary to assure sufficient thermal mass is maintained during low water conditions and prolonged droughts. The CGC (2010) also mentions that in cold climates, if a water body depth is less than 3m, lakes and dams destratify and offer no advantage. Due to flooding and droughts as well as hazards due to moving debris that can damage the geothermal ground loop, rivers are not ideal for this application.

Open Loop Heat Sources

An open water loop system involves water being removed from the ground or body of water and returned after heat is extracted or added. Clearly, considerable care must be directed at the location of the return system so that the discharge water does not affect the intake temperatures. One of the major advantages of these systems is that relatively large volumes of water can be handled leading to large quantities of heat exchange.

An open water loop system involves water being removed from the ground or body of water and returned after heat is extracted or added. Clearly, considerable care must be directed at the location of the return system so that the discharge water does not affect the intake temperatures. One of the major advantages of these systems is that relatively large volumes of water can be handled leading to large quantities of heat exchange.

Energy Pile Ground Heat Exchanger

In an urban environment, the ground immediately below a city can be used as a low-grade energy storage reservoir. Geotechnical structures such as piles, tunnels, sewers, retaining walls and ground slabs can be regarded as thermo-active structures by simply embedding geothermal ground loop pipes in them. For example, if the building is a large commercial or industrial building with significant foundations including large diameter piles, then it is almost certain that these elements will provide the location for the geothermal ground loop.

Ground Source Heat Pump (GSHP)

According to the Second Law of Thermodynamics, heat cannot by itself move from a lower temperature to a higher temperature (just as water cannot by itself flow uphill). Heat pumps on the other hand, can move heat from lower temperature to higher temperature regions (just as water pumps can move water uphill). Heat pumps are typically used to transfer the ground’s energy to heat or cool buildings. The principle of a heat pump is illustrated in Figure below for the cooling mode of operation of a water to air heat pump.

The operation of a Ground Source Heat Pump (GSHP) in cooling mode of operation (IGSHPA 1988)

As shown in Figure above, in cooling mode of operation, water from the ground loops passes through the primary circuit heat exchanger (the condenser) of the heat pump. Here, this water comes into indirect contact with the warmer gas refrigerant. Heat passes from the warmer gaseous refrigerant to the cooler water. As a result of the removal of heat from the refrigerant, it condenses to a liquid phase at a relatively high temperature. When this liquid then passes through an expansion valve, the temperature drops considerably ready to accept heat from the conditioned space. Heat passes from the warmer air from the conditioned space to the liquid refrigerant to cause it to evaporate. The gaseous refrigerant then passes into a compressor where the gas is compressed to significantly increase not only its pressure but also its temperature. The hot gas then passes through the condenser again and the refrigeration cycle continues. Read more In the cooling mode of operation, the heat generated by the compressor is not a useful and together with the heat extracted from the building, should be rejected to the ground. In the heating mode of operation, the waste heat generated by the compressor electricity consumption is useful energy and is delivered to the building to assist in heating. The heat flux delivered at the condenser of a heat pump to the building is the sum of heat flux extracted from the evaporator/geothermal ground loop and the electric power consumed by the compressor. The “efficiency” of a heat pump is expressed as a coefficient of performance (CoP). This is defined as the ratio of heat delivered to the building( Qb in kW ) to electricity consumption of heat pump(QE in kW) : QE in

Why Geothermal?

The key to the geothermal system is that for each kilowatt of electrical energy put into a geothermal system, depending on several parameters, about 4 to 5 kilowatts of energy is developed for the purposes of heating and cooling. This means that geothermal systems could reduce electricity demand for heating and cooling by 75%. Furthermore, as much of the electrical power in Victoria is generated with brown coal, replacing 75% of the energy used with a clean and free renewable energy source, these systems will have the potential to significantly cut Australia’s carbon footprint.

The key to the geothermal system is that for each kilowatt of electrical energy put into a geothermal system, depending on several parameters, about 4 to 5 kilowatts of energy is developed for the purposes of heating and cooling. This means that geothermal systems could reduce electricity demand for heating and cooling by 75%. Furthermore, as much of the electrical power in Victoria is generated with brown coal, replacing 75% of the energy used with a clean and free renewable energy source, these systems will have the potential to significantly cut Australia’s carbon footprint.

Geothermal vs VRF split system

It is apparent that due to the thermodynamic advantages of rejecting heat to or extracting heat from the ground rather than air, the Geothermal system has better operational efficiency. However, the question is how they compare with the conventional systems for the same building.

The ASHRAE headquarters building was refurbished in 2008 and was transformed into a living lab for assessing the real performance of high-efficiency heating and cooling systems in an operational office building environment.

The ASHRAE headquarters building was refurbished in 2008 and was transformed into a living lab for assessing the real performance of high-efficiency heating and cooling systems in an operational office building environment.

The assessed geothermal system in this study serves a single separate floor and includes 14 individual water-to-air heat pumps (2.6 kW), six 7 kW units, and six 10.5 kW heat pumps connected to a ground loop consisting of 122 m deep vertical boreholes, for a total of 111 kW of cooling capacity. The heat pumps have variable speed fans (driven with electronically commutated motors) with three selected speeds.

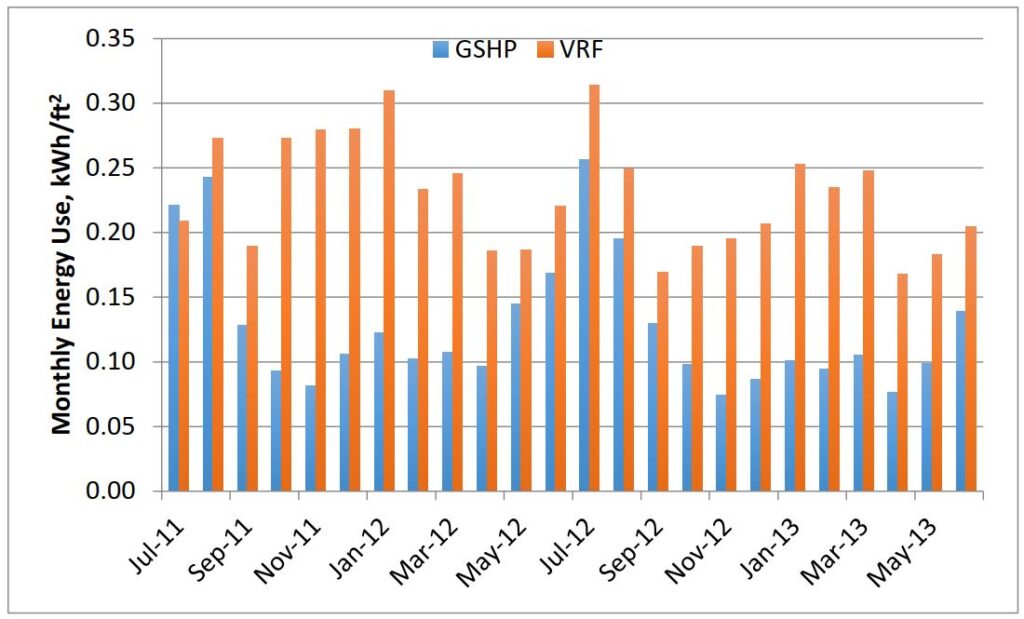

For the two-year time span of this study, the conventional VRF split system used 98% more total energy than the Geothermal system, 41% more in the summer cooling season and 172% more in the winter and shoulder seasons. Figure below compares the electric power demand of the geothermal system and the conventional VRF split system for each month in Atlanta, Georgia USA.

Factors contributing to the differences in energy use include ground loop water supply temperatures being more favourable than ambient air temperatures for heat pump operation. This allows the GSHP equipment to operate at higher efficiency. The control strategy of the VRF system resulted in longer runtimes than the GSHP system, especially in mild weather. These longer runtimes coincided with significant amounts of simultaneous cooling and heating in adjacent spaces.

You can read more about this comparison in the following articles published in ASHRAE Journal:

L.E. Southard, L., E., Xiaobing L., Spitler J., D., 2014 Performance of HVAC systems at ASHRA HQ. ASHRAE Journal.

Spitler J., D., Xiaobing L., 2014 Performance of HVAC systems at the ASHRA Headquarters Building. Final Report (109 pages).

Note that the above cost-saving and energy use reduction applies to a local climate and can’t be automatically attributed to any climate as the conventional system operation is heavily affected by the ambient air temperature. Similar savings may not be achieved in different climates. It is crucial to calculate the efficiency of the geothermal and conventional air-source system (a normal split system or a VRF split system) for every hour of the day and year as it can vary by up to 100%. At GeoHeat we deliver hour-by-hour energy modeling to calculate the hour-by-hour cost-saving before presenting a solution to our clients. Unfortunately, only a few appear to be doing this in Australia.

Also note that, if a geothermal system is not designed correctly, a normal off-the-shelf split air conditioner might be more efficient as it has been engineered in a factory.

At GeoHeat, our recommendations to people looking for installing a geothermal system are:

- Get an hour by hour feasibility assessment done for your building and local climate so you can see what you can realistically expect to achieve with your investment in Geothermal,

- Get it designed properly by an engineer (hour by hour analysis) and not based on rules of thumb and,

- A geothermal system is a plumbing work and it is installed by a plumber. Make sure your design engineer or an IGSHPA accredited professional reviews the plumbing works and commissions the geothermal system for you.

Hydronic in slab heating

During the last two decades, radiant floor heating applications have increased significantly. In Germany, Austria and Denmark, 30% to 50% of new residential buildings have floor heating. In Korea, about 90% of residences are heated by underfloor systems.

Indoor air quality

Floor heating also prevents cold corners and due to the higher surface temperatures, there is less chance for condensation and mould growth. The German Allergy and Asthma Association has produced a study that shows that floor heating reduces the favourable living conditions for house dust mites compared to other heating systems. Higher temperatures in carpets and mattresses decrease the relative humidity. Also, because mites seek the upper areas, they are more easily removed by vacuum cleaners. Another study found a lower level of dust mites in Korean houses than in Japanese houses. This was attributed to the same effect but was not directly verified.

Floor Surface Temperature

In international standards, a floor temperature range of 19°C to 29°C is recommended in the occupied zone for rooms with sedentary and/or standing occupants wearing normal shoes. This is a limiting factor for the capacity of floor systems. For heating, the maximum temperature is 29°C, and for cooling, the minimum temperature is 19°C. In the European standard, it is acceptable to use 35°C as the design floor temperature outside the occupied zone, i.e., within 1 m from outside walls/windows. In spaces where occupants may have bare feet (bathrooms, swimming pools, dressing rooms), the optimal floor temperature for comfort also depends on the floor material.

Design of hydronic system

In the ASHRAE Handbook—HVAC Systems and Equipment (Chapter 5) and in the European standard for floor heating, a method is given to calculate the heating capacity of a floor system. The heat exchange coefficient at design conditions is 11 W/m²·K. At smaller temperature differences between floor surface and space, this will decrease to about 9 W/m²·K. Of the total heat exchange, more than half is due to radiation (~5.5 W/m²·K). The maximum capacity in the occupied zone is about 100 W/m² at 29°C floor temperature and 20°C room temperature. A higher floor temperature like a maximum of 35°C may be used within 1 m from the outside walls/windows and for a 20°C room temperature this results in a heat output of 165 W/m².

This maximum heating capacity is independent of the type of floor covering (tiles, wood, carpet). The required water temperature to obtain the maximum heating capacity is, however, dependent on the thermal resistance of the floor covering and other factors such as system type and pipe spacing. The standard lists factors to account for these parameters.

Need more information or a quote?

Speak to our experts or get a quote now!

Contact us:

Address:

24 Aisbett Avenue,

Camberwell, vic 3124

ABN:

27610168842

GEOFLOW AUSTRALIA PTY LTD